We are continuously expanding our machine park. In the medium term, we are investing in innovative surface engineering. Currently and in addition to the usual workshop machinery, we are equipped with the following technologies:

5-Axis Machining Center

This is equipped with a turntable for 800 mm components and a machining area of up to 6000 mm in length. The machining center is a CNC controlled 5 axis tool machine, designed for complete machining of components (6000 x 900 x 950 mm).

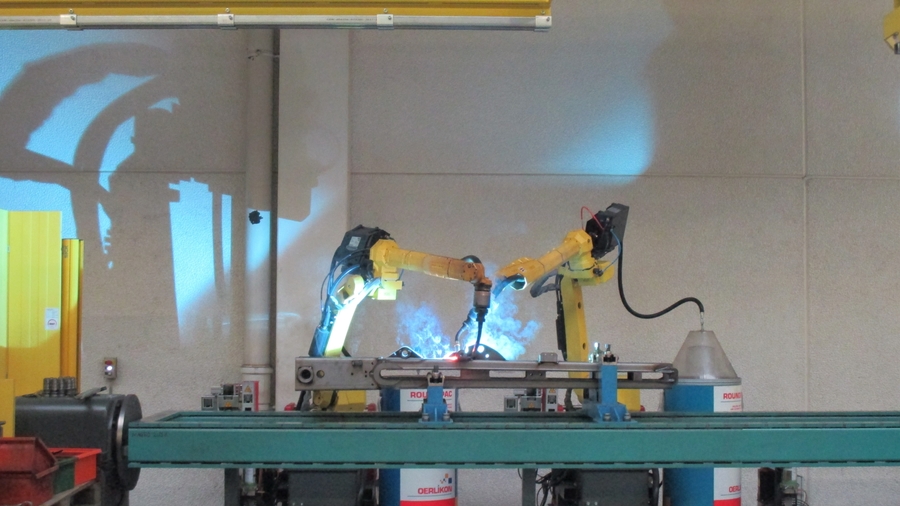

Several robotic welding units also with dual robots

These enable simultaneous low-delay welding, with a tool (fixture) quick-change system. We also maintain compact welding cells for smaller components. Our positioner can handle between 1600 mm and 7000 mm (max.) fixture length and 2 tons in weight.

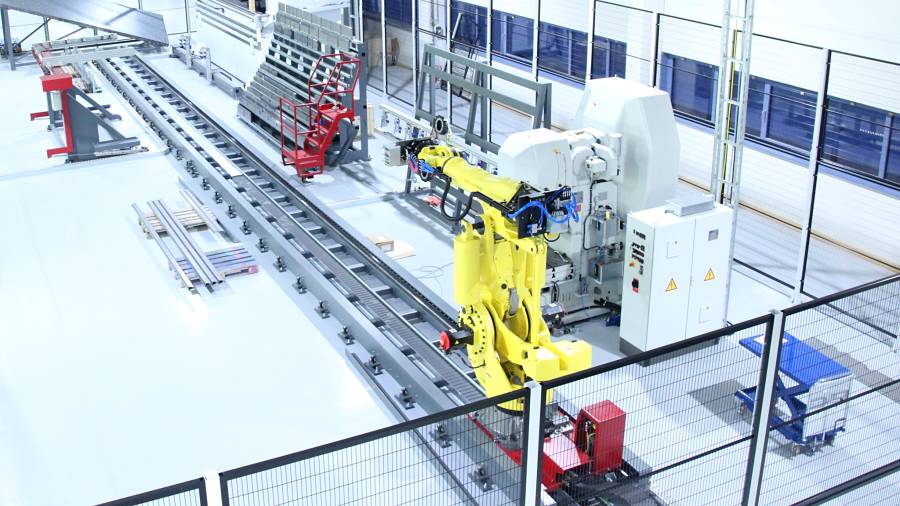

Fully automatic Edging/Stamping Center

Metal sheet components with a length of up to 6000 mm are manufactured here in full and with high precision. Press force is 600 tons. We are equipped among others with a 6-axis-mechanical stop and laser angle measuring sensor technology. Components weighing up to 700 kg are handled by robots. Tool remodeling is also possible using our available C-frame pneumatic press.

Various manual welding stations for MAG Welding

These enable the application of metal active gases (MAG), which leads to improved welding results. Active gases used are in accordance with requirements.

Flatbed Laser 6 KW

This is suitable for the machining of sheet metal measuring of up to 4 m x 2 m x 25 mm thickness.

Press Brake 230 Tons

Up to 4 m length, equipped with a 6-axis-mechanical stop and Laser-angle measurement sensor technology.

Assembly Department

For example, this department has individual work desks for manual fitting and assembly, but also whole assembly lines for series production, order picking and packaging.

Quality Control

QM Is carried out using state-of-the-art 3D measuring technology and software, in line with inspection protocols. Another important quality aspect is our lived continual improvement philosophy.